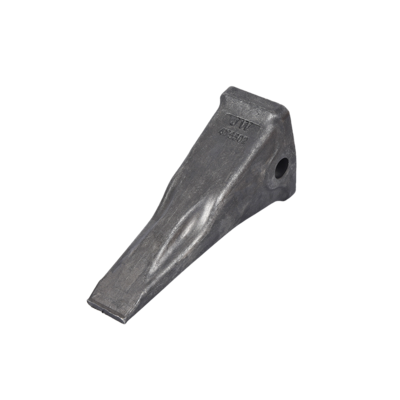

Can over-digging cause damage to bucket teeth?

Excessive excavation can indeed cause damage to the bucket teeth. In excavation operations, the buck...

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

As China Forged Bucket Teeth Suppliers and Forging Bucket Teeth Company, Zhejiang Jiwang Forging Technology Co., Ltd. is an innovative material company, founded in 2017.Through process innovation and new material research and development, Zhejiang Jiwang Company has successfully developed China's first forged bucket teeth.This is a disruptive technology, which completely solves the environmental protection problems in the process of casting bucket tooth manufacturing, and has an important impact on the development of China's bucket tooth industry.In 2020, the company will receive 25 million yuan of investment for the construction of the world's first fully automated production line in the subdivision field of forging bucket teeth.Bring the production process of excavator forging bucket tooth into the 2.0 era.The production line has been put into operation since October 2021, with an annual production capacity of 15,000 tons, and the company has a total annual production capacity of 20,000 tons.At present, We supply Forging Bucket Teeth Custom, the company has complete product models, reliable product quality, and strong product supply ability.Provide competitive products at home and abroad.

Excessive excavation can indeed cause damage to the bucket teeth. In excavation operations, the buck...

Old bucket teeth can be reused under specific conditions, but this depends on multiple factors such ...

After the wear of the bucket teeth, they can be repaired and reused in most cases. As a key componen...

The bucket teeth do indeed generate noise pollution during use. During excavation, loading, and othe...

The use of bucket teeth itself does not directly affect the water body, as bucket teeth are a compon...

No. 126, Haiying Road, Binhai Industrial Park, Xiangshan County, Zhejiang Province China

+86-15058464226

+86-0574-65880078