Sany Bucket Teeth: The Importance of Quality Materials and Precision Manufacturing

When it comes to heavy equipment, the quality of the components used can make a big difference in the performance, durability, and efficiency of the equipment. This is particularly true when it comes to bucket teeth, which are essential components of excavators, loaders, and other heavy equipment used for digging and moving materials. Sany bucket teeth are known for their high-quality materials and precision manufacturing processes, which contribute to their superior performance and durability.

Quality Materials

Sany bucket teeth are made from high-quality materials, such as alloy steel, that are carefully selected for their strength, durability, and wear resistance. The materials used in Sany bucket teeth are designed to withstand the harsh conditions of heavy equipment use, including abrasion, impact, and extreme temperatures. This ensures that the bucket teeth can perform efficiently and last longer, reducing the need for frequent replacements and maintenance.

Precision Manufacturing

In addition to high-quality materials, Sany bucket teeth are manufactured with precision and attention to detail. Sany uses advanced manufacturing processes, such as computer-aided design (CAD) and computer numerical control (CNC) machining, to ensure that each bucket tooth is manufactured to exact specifications. This precision ensures that the bucket teeth fit perfectly with the rest of the equipment and perform optimally, reducing the risk of downtime or equipment failure.

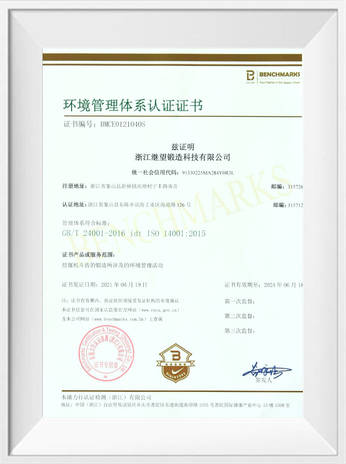

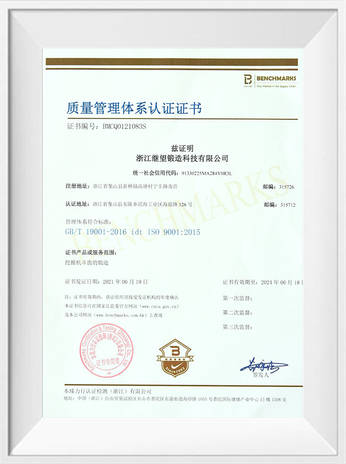

Quality Control

Sany also implements rigorous quality control measures to ensure that each bucket tooth meets the highest standards of quality and performance. The bucket teeth undergo a series of tests to ensure that they meet the required hardness, wear resistance, and impact strength. This ensures that the bucket teeth can withstand the demanding conditions of heavy equipment use and perform reliably over time.

In summary, the quality of the materials and precision manufacturing processes used in Sany bucket teeth are essential factors in their performance and durability. The use of high-quality materials and advanced manufacturing processes, combined with rigorous quality control measures, ensures that Sany bucket teeth can withstand the harsh conditions of heavy equipment use and perform efficiently over time.

The Benefits of Sany Bucket Teeth for Quarrying Operations

Quarrying operations require heavy equipment that can withstand the harsh conditions of extracting and moving large quantities of stone and rock. Sany bucket teeth are designed to meet these demands and provide a range of benefits for quarrying operations. Here are some of the key benefits of Sany bucket teeth for quarrying operations:

Superior wear resistance: Sany bucket teeth are made from high-quality materials that provide superior wear resistance. This means that the bucket teeth can withstand the abrasive effects of extracting and moving stone and rock, reducing the need for frequent replacements and maintenance.

High strength: Sany bucket teeth are designed to withstand the high impact forces that occur during quarrying operations. They are made from strong and durable materials that can withstand the heavy loads and stresses of moving large quantities of material.

Optimal penetration: Sany bucket teeth are designed to penetrate the ground with minimal resistance, making them more efficient at extracting material. This reduces the time and effort required to move large quantities of stone and rock, increasing productivity and reducing costs.

Easy replacement: Sany bucket teeth are designed to be easily replaced, reducing downtime and maintenance costs. The bucket teeth can be quickly and easily removed and replaced when they become worn or damaged, allowing the equipment to resume operation with minimal interruption.

Compatibility: Sany bucket teeth are designed to be compatible with a range of heavy equipment used in quarrying operations, including excavators and loaders. This means that they can be used across different types of equipment, reducing the need for specialized equipment and simplifying maintenance and replacement.

In summary, Sany bucket teeth provide a range of benefits for quarrying operations. They offer superior wear resistance and high strength, enabling them to withstand the harsh conditions of extracting and moving large quantities of stone and rock. They also provide optimal penetration, easy replacement, and compatibility with a range of heavy equipment, increasing productivity and reducing costs.